Reduce Total Cost of Ownership, Improve Productivity

- Higher-airflow system (900 CFM, 25.48 m3 /min) for larger machines protects the engine with sustained clean air, regardless of operating state, even at idle

- High-efficiency filtration arrests smaller particles, extending life of engine and after-treatment systems

- Minimize downtime and maintenance costs

- Maximize primary engine filter life

- Easy to install, including vertical and horizontal mounting options

Protect Heavy Mobile Equipment Operators in High-debris Work Environments, including:

- Mining

- Demolition

- Construction

- Quarries / aggregate

- Concrete processing

- Waste and recycling, landfills, and transfer stations

- Agricultural and harvesting

- Forestry and timber

- Other high-debris job sites

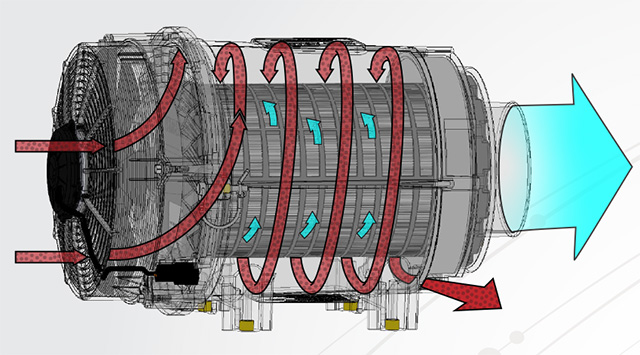

How it works: The “Sy-Klone Effect”

- Dirty air enters the precleaner housing through the inlet end.

- The debris-laden air is directed into a rotation – a “Sy-Klone” – pushing the debris to the outside walls through centrifugal force. The debris rotates towards the outlet end.

- Debris is ejected through the ejection port, and the fine dust that remains passes through Sy-Klone’s self-cleaning filter.

- After passing through the high-efficiency filter, clean air is passed downstream to the HVAC system through the outlet end.

The separation and ejection of debris, and high-efficiency filtering, all of which precleans air, is The Sy-Klone Effect!

Product Specifications

Airflow range: 0-900 CFM (0-25.48 m3/min)

Mounting: Vertical or horizontal (Mounting plates available separately)

Voltage: 12V and 24V options available

Power requirement: 10.5 amps constant at 12V; 8 amps constant at 24V

Product dimensions and weight: HxWxL; Weight

With rain cap: 13.3″ x 14.3″ x 24.1″ (337 mm x 364 mm x 611 mm); 17 lbs. (7.7 Kg)

Without rain cap: 13.2″ x 14.3″ x 21.5″ (336 mm x 364 mm x 546 mm); 15.5 lbs. (7.0 Kg)

With heavy-debris screen: 14.5″ x 14.5″ x 26.2″ (368 mm x 369 mm x 665 mm); 21.8 lbs. (9.8 Kg)